Tel:+86 0538-8932577/8932579

Fax:0538-8933808

Email:tkhgqscb@163.com

Email:tkhgqzhb@163.com

Address: Shandong Tai'an

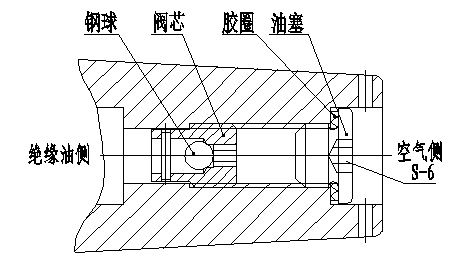

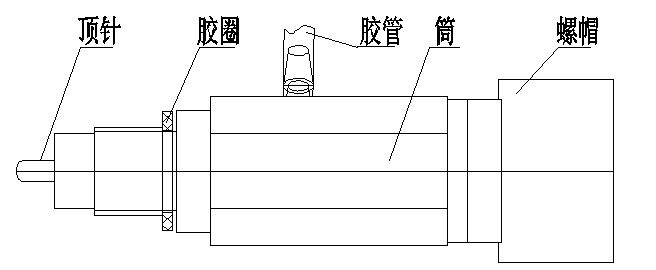

1, put the oil valve, take the oil sample tooling structure

The oil drain valve structure shown in Figure 7, take oil sample tooling structure shown in Figure 8.

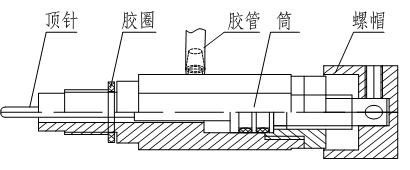

Figure 8 take oil sample tool structure

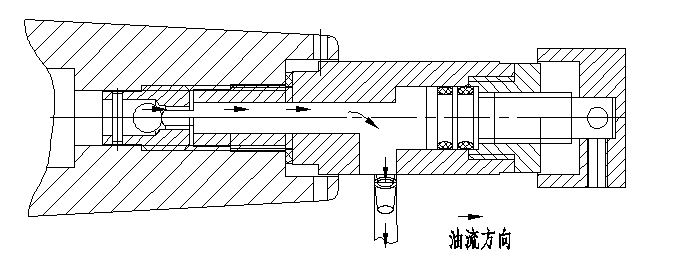

1, take the oil sample flow

Take oil sample diagram shown in Figure 9.

Figure 9 Schematic diagram of the oil sample

1) Turn the nut of the oil removal tool counterclockwise to the limit.

2) With S = 6 hex wrench to remove the oil plug shown in Figure 7, is strictly prohibited to remove the spool.

3) As shown in Fig. 9, install the oil removal tool on the oil filling valve and fasten it.

4) Turn the nut on the oiling tool clockwise until the transformer oil flows smoothly from the tubing. The speed of the oil flow can be controlled by the size of the screw inwardly.

5) After oil removal, remove the nut from the tooling to the limit by counterclockwise rotation, remove the oil from the oil after the transformer oil is no longer flowing out, then tighten the oil plug, wipe the oil traps at the oil drain valve Clean, check the oil plug at no leakage.

1, attention to matters

1) When installing the oiling tool, do not screw in too fast and force too hard. If it is difficult to install, it is forbidden to carry out barbaric operation. It is necessary to withdraw the oiling tooling and check the thread for damage. Lax and oil spills.

2) As the product is less oil products, do not recommend on-site oil. If it is necessary to take the oil, the oil should be in accordance with the relevant procedures to take, check the oil level after oil, if the oil level is lower than the MIN position should be promptly replenishment, the insulating oil must be filled with oil equipment The same model, with the quality.

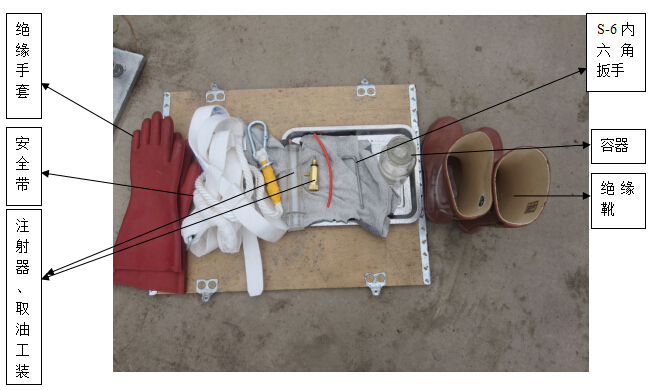

On - site Oil Pick - up Transformer and Precautions

1, need to prepare the tooling, equipment

2, check and ensure that the oil tooling is intact, will take the oil tooling out of the nut to the limit.

3, check the ground wire is safe and reliable, to ensure safe and reliable grounding grounding.

4, the two highly suitable insulation ladder leaning against the current transformer bracket, to ensure that the ladder is stable and reliable.

5, from the scene to find a person to help take oil samples, mainly holding oil containers.

6, the two climbed to the appropriate height along the insulated ladder, a person responsible for loading and unloading oil valve on the oil plug and oil tooling, one is responsible for taking the oil container and then release the transformer oil.

7, if the product is charged running, take any part of the body when the oil can not be higher than the height of the transformer base.

8, is responsible for loading and unloading oil plugs and oil tooling people, one hand and a wrench, a good grasp of the ground line. Contact with the ground wire may be static electricity Ma phenomenon, to a one-time grasp the ground line, if there is insulation gloves, then wear insulated gloves.

9, do a good job grounding line, the first with cotton yarn oil discharge valve at the erase clean, and then by the way the 3 oil.

10. Remove the oil plug with an S-6 Allen wrench.

11, with an open-end wrench to the oil with the oil workers to install the oil drain valve and tighten.

12, will take the oil on the tooling to screw into the screw, until the transformer oil smoothly from the tubing in the release. The speed of the oil flow can be controlled by the size of the screw inwardly.

13, after the end of the oil will take the oil out of the tooling on the nut out of the transformer oil is no longer out of the oil after the wrench with an open wrench to remove the tooling, and then S-6 hex wrench to the oil plug fastening, With the cotton yarn will be placed in the oil valve wipe clean oil traces, check the oil plug at the oil leakage before leaving.

Fourth, pay attention to matters:

1, rain, humidity and process requirements may not be carried out in the oil environment, the operation is not allowed to take oil.

2, with an open-end wrench to install the oil removal tooling, it is necessary to slowly screw into the fast is not easy, and hard not too large, difficult assembly encountered not barbaric operation, the need to withdraw the oil tooling and check the thread for damage, so as not to damage the release Oil valve at the thread, resulting in tight and leaky oil seal.

3, with the S-6 hex wrench disassembly, installation of oil plug, the force is not easy too much, too fast, so as not to damage the oil drain valve at the thread, resulting in tight and leaky oil seal.

4, take oil after the oil plug must be reset and tightened to prevent the installation of the oil plug due to forget the product caused by oil spills.

5, each take the oil to meet the needs of the principle, not easy to take too much oil.

6, take oil before and after, pay close attention to the expansion of the oil level mark, the oil level is lower than the "MIN" to timely replenishment.

Take care to keep the oil drain valve and the container clean, take the finished product according to the number of oil in the oil container to write the appropriate number, and sealed to keep the container external clean.