Tel:+86 0538-8932577/8932579

Fax:0538-8933808

Email:tkhgqscb@163.com

Email:tkhgqzhb@163.com

Address: Shandong Tai'an

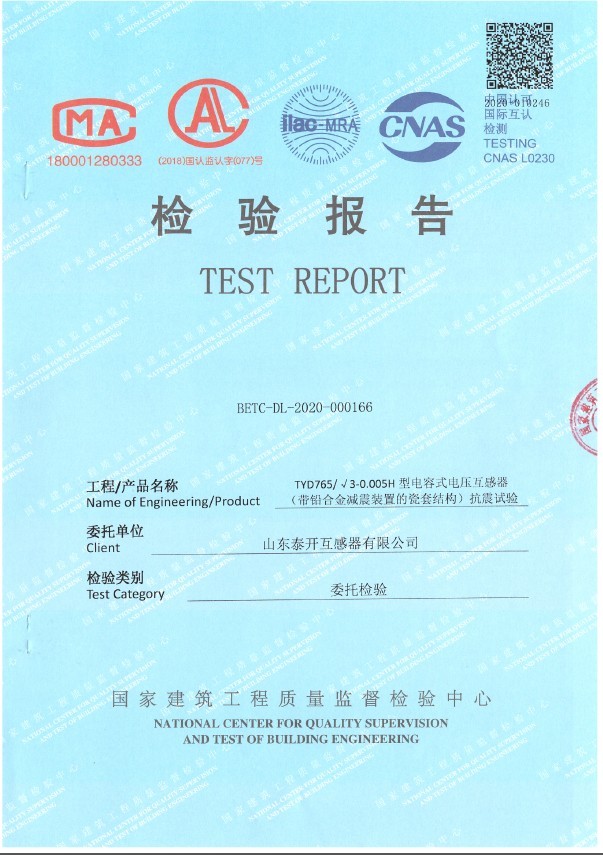

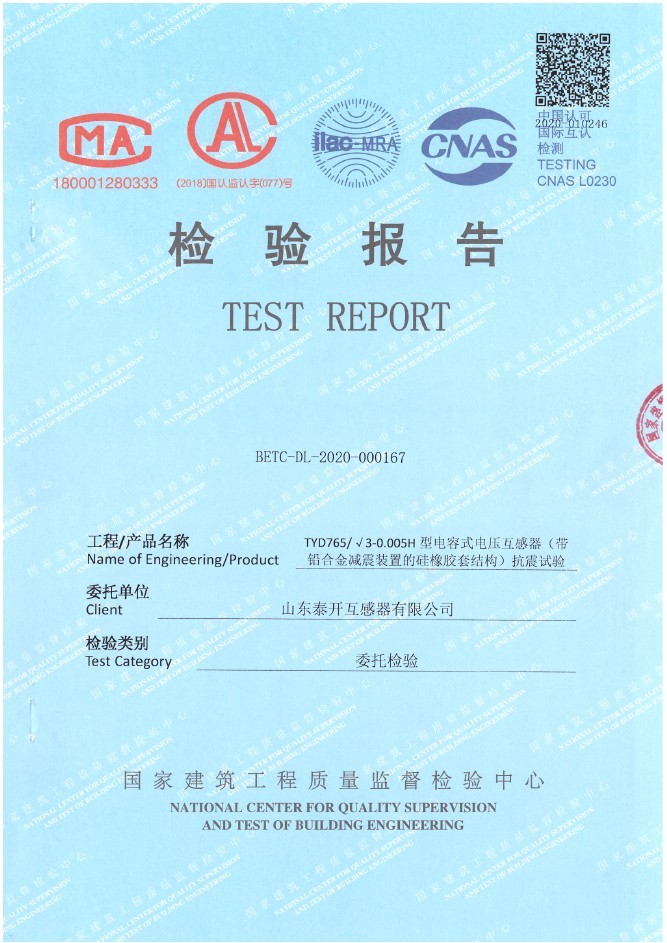

In December 2020, TYD765/0.005H capacitive voltage

transformer produced by Shandong Taikai Instrument Transformer Co., Ltd.

successfully passed the seismic test in China Academy of Building Research Co.,

Ltd. (National Center for Quality Supervision and Test of Building Engineering).

The transformer is divided into two structural types: porcelain bushing and

composite bushing. Both types have passed 8-degree intensity seismic test

required by the standard at one time. Among them, the composite bushing product

passed 9-degree (0.5g) intensity allowance test,which is the highest level in

China.

TYD765/0.005H is an ultra-high voltage capacitive

voltage transformer independently developed by our company. The product is

designed with domestic leadership as the goal. While ensuring excellent

electrical performance, the R&D team uses professional software to

accurately simulate and optimize the force and seismic performance of the

product. Through the bushing strength segmented control technology and new

metal damping devices application, major breakthroughs have been made in

improving the seismic performance of ultra-high voltage units. The transformer

has passed all seismic tests at one time, and its seismic performance is better

than GB 50260 " Code for design of seismic of

electrical installations", Q/GDW11391 "Technical Regulations for

Seismic Test of High-Voltage Pillar Electrical Equipment". The technical

indicators of the transformer have reached the leading domestic industry level.

The outstanding performance of 765kV capacitive voltage

transformer on seismic test demonstrates the company's consistent quality

strength, and also enhances brand awareness and products’ market

competitiveness.

Fig.1- Site test and test report of porcelain bushing structure product

Fig.2- Site test and test report of composite bushing structure product